Introduction to Modular Conveyor Belt Innovation

In today’s fast-paced industrial world, companies are constantly seeking new ways to streamline operations, cut costs, and increase output without compromising on quality. One of the most impactful innovations in modern manufacturing and logistics has been the modular conveyor belt. Designed to offer adaptability, durability, and efficiency, the modular conveyor belt has become an essential solution for many businesses. Thus, it is no surprise that demand for Hairise’s Plastic chain conveyor systems continues to grow across industries.

What Makes Hairise Modular Conveyor Belt Systems Unique

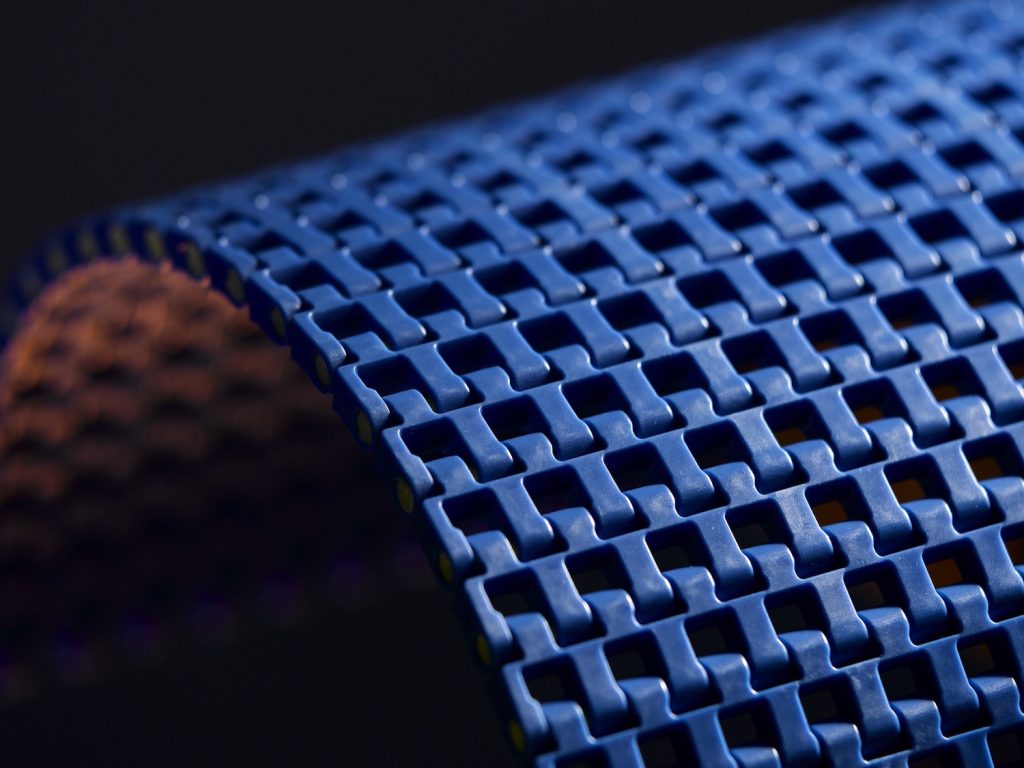

Hairise has developed its modular conveyor belt systems with over 20 years of expertise, blending engineering excellence with market-specific customization. These systems are not generic—they are industry-tailored solutions designed for long-term performance. Hairise engineers ensure that each modular conveyor belt is built with premium thermoplastic material that can withstand heat, chemicals, and rigorous cleaning. Unlike conventional belts that tear or stretch, Hairise’s Plastic chain conveyor resists wear and deformation. This durability reduces the frequency of replacements and repairs, saving operational costs. Moreover, Hairise systems are modular in the truest sense, offering tool-less assembly and disassembly. Businesses benefit from this because a Plastic chain conveyor can be easily upgraded or reconfigured as production demands shift. This modularity makes the system a future-proof investment. The belts also support automation integrations such as sensors, diverters, and counters, making them perfect for Industry 4.0 standards. When combined with low-friction surfaces and energy-efficient motors, Hairise’s modular conveyor belt systems ensure reduced power consumption and operational noise.

Applications of Modular Conveyor Belt in Various Industries

Hairise’s Plastic chain conveyor systems are versatile, making them a go-to choice for several sectors. In the food and beverage industry, hygiene is paramount. Hairise uses FDA-approved materials for their modular conveyor belt, ensuring compliance with strict safety standards. The open hinge design allows thorough cleaning and rapid drying, eliminating bacterial risks. In automotive industries, the modular conveyor belt is ideal for handling heavy parts with minimal wear. It also supports accumulation and indexing, which are critical for assembly lines. In the packaging industry, high-speed processing is a must. The smooth surface of the Plastic chain conveyor ensures products are moved swiftly without damage or misalignment. For pharmaceuticals, Hairise offers anti-static Plastic chain conveyor options that prevent contamination. Even the electronics industry benefits, as ESD-compliant belts protect delicate components during transfer. These industry-specific adaptations showcase the immense utility of the Hairise modular conveyor belt.

Customization and Modularity: The Core of Hairise Systems

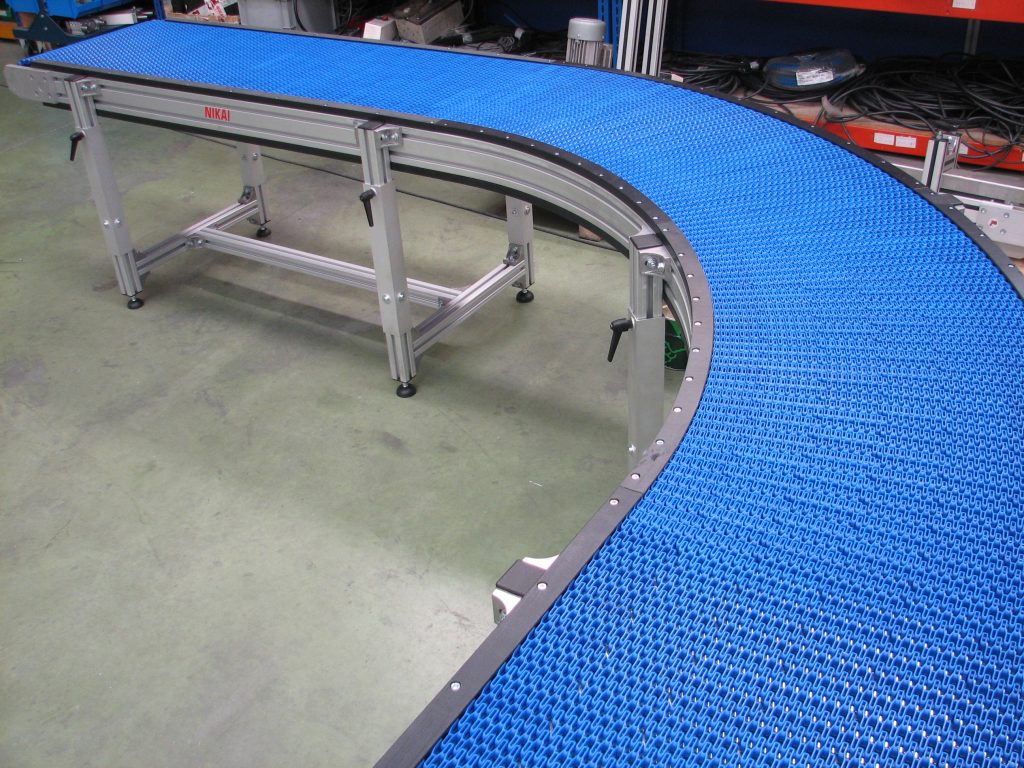

One of the biggest advantages of choosing a Hairise Plastic chain conveyor system is the incredible customization potential. Production facilities rarely have identical layouts or throughput needs. Hairise addresses this by offering belts in different widths, materials, and module shapes. A business can select a modular conveyor belt that best fits curves, inclines, or specialized workstations. Even the color of the belt can be customized to fit safety codes or branding preferences. Additionally, Hairise provides simulation and CAD modeling services. Engineers use these tools to create a Plastic chain conveyor layout that maximizes space efficiency and flow rate. Once designed, the system is assembled with plug-and-play simplicity. This ensures businesses face minimal disruption during installation. If expansion is needed later, adding new modules is straightforward and does not require system overhaul. A modular conveyor belt from Hairise can grow with your operation, maintaining performance while adapting to new challenges.

Easy Maintenance and Reduced Downtime

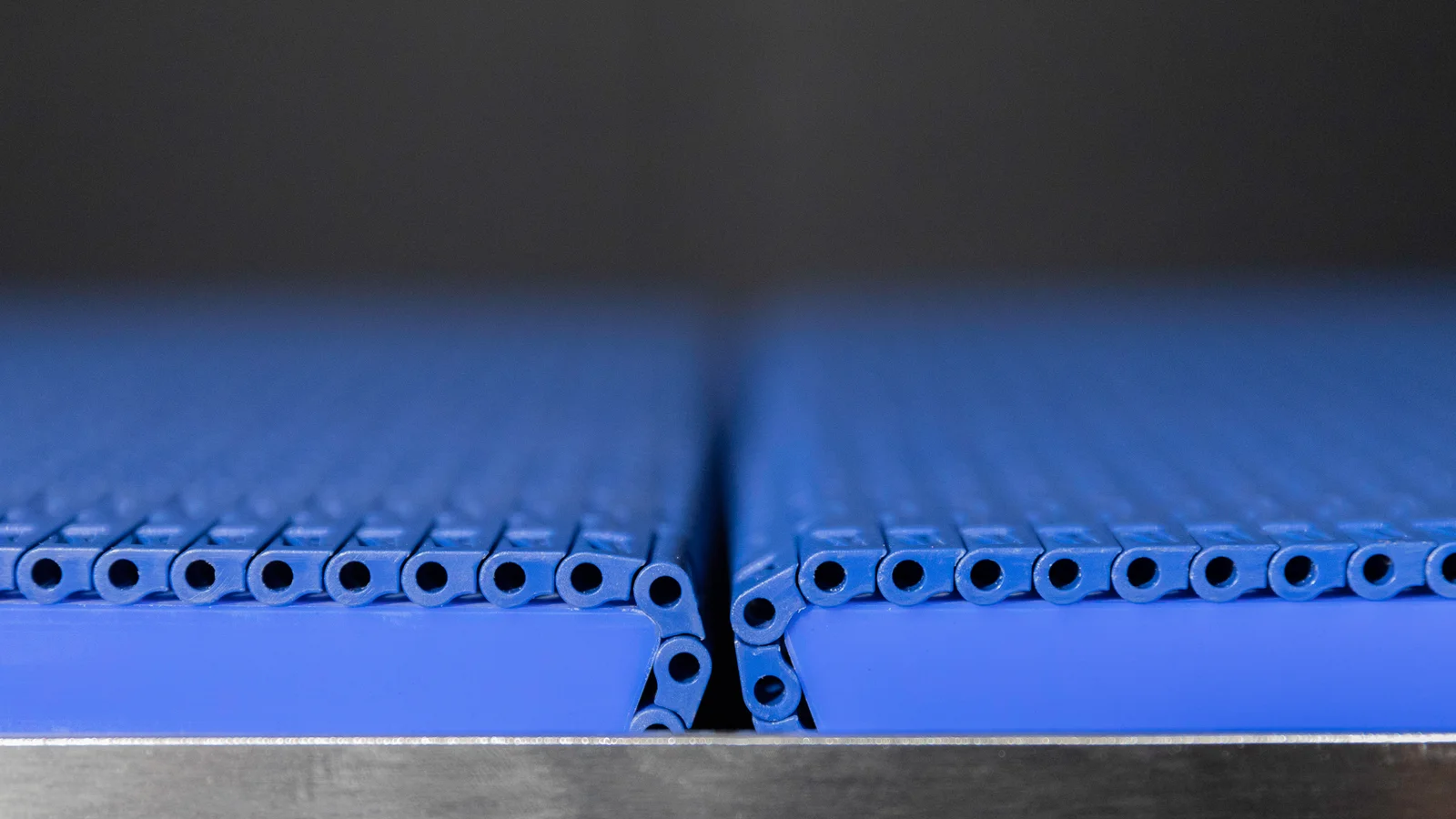

In traditional conveyor systems, even minor issues can halt production and lead to hours of lost productivity. Hairise has eliminated that problem with its modular conveyor belt design. Since the belts are composed of interlocking plastic modules, individual sections can be removed and replaced without dismantling the entire line. This makes servicing a Hairise Plastic chain conveyor incredibly fast and cost-efficient. Additionally, the plastic construction means there’s no need for lubrication, which avoids messy, time-consuming maintenance. Many models feature self-lubricating properties and noise-reducing designs, which extend equipment life and reduce operator fatigue. Hairise also offers predictive maintenance tools. These tools monitor wear patterns and alert users when a module in the modular conveyor belt needs replacing. As a result, businesses can schedule downtime during off-peak hours, ensuring continuous operation. The simplicity and practicality of maintaining a modular conveyor belt by Hairise cannot be overstated.

Environmental Benefits of Modular Conveyor Belt Systems

Sustainability is a priority for modern industries, and Hairise recognizes this need. Their modular conveyor belt systems are engineered to reduce environmental impact. The belts use recyclable thermoplastics, which minimize landfill waste. Additionally, they consume less energy due to their low-friction surfaces. Because a Hairise Plastic chain conveyor is highly durable, it doesn’t require frequent replacement, which lowers material consumption over time. Hairise also supports green operations by offering water-saving cleaning designs. For instance, open hinge modules allow faster cleaning with lower water pressure. Moreover, since the Plastic chain conveyor does not rust, businesses avoid chemical corrosion treatments. This significantly lowers the use of toxic agents and improves worker safety. By investing in a modular conveyor belt from Hairise, businesses make a commitment not just to efficiency, but also to environmental stewardship.

Boosting Production Speed with Optimized Layouts

A modular conveyor belt is not just a transportation tool—it is an engine for productivity. Hairise helps clients design layouts that maximize output. For example, production lines using multi-tiered modular conveyor belt setups can process several items at once, drastically improving throughput. Curved and spiral designs minimize space while extending conveyor length. These configurations are particularly useful in space-constrained environments. Inclined belts can connect multiple floors, eliminating manual material movement. Hairise’s modular conveyor belt can be integrated with robotic pickers, vision systems, and diverters to enable smart sorting and handling. This level of optimization ensures that production never lags. Companies using Hairise report measurable improvements in cycle times and error reduction. The smart layout possibilities of a modular conveyor belt system can become a major competitive advantage in crowded markets.

Cost-Effectiveness and ROI

Initial investment in a Hairise modular conveyor belt system may seem significant, but it pays off quickly. Reduced downtime, lower maintenance, and enhanced productivity translate to faster returns. Over time, the modular conveyor belt system becomes more economical than traditional alternatives that require frequent servicing. Hairise provides clear ROI estimates based on your production goals. For instance, food processing units that switch to Hairise often experience a 30% increase in output within the first quarter of installation. Additionally, savings from energy efficiency and water reduction contribute to long-term profitability. Businesses also save on labor, as the modular conveyor belt automates manual handling tasks. Because of its modular design, expansion is cost-efficient too. You don’t need to replace the entire system—just add new segments. Hairise also offers affordable spare parts and quick delivery, ensuring minimal disruption if a repair is ever needed. Choosing a Hairise modular conveyor belt is a smart financial decision.

Safety and Compliance Features

Workplace safety is another area where the Hairise modular conveyor belt shines. Each unit is designed to meet or exceed local and international safety standards. Belt edges are smooth and rounded, reducing injury risk. In food-grade models, Hairise ensures that all modular conveyor belt materials are non-toxic and meet FDA, USDA, and CE regulations. Many systems feature slip-resistant surfaces, which are essential in wet environments. Additionally, emergency stop features and safety covers can be easily integrated. Unlike steel belts, the Hairise modular conveyor belt doesn’t generate heat or conduct electricity, improving safety for operators. The company also provides training support, ensuring your staff knows how to operate and maintain the system safely. Compliance with hygiene and safety regulations is critical, especially in sensitive industries, and Hairise’s modular conveyor belt systems make it easier to meet those requirements with confidence.

Why Choose Hairise Over Competitors

When it comes to quality and performance, Hairise stands out in the modular conveyor space. With more than two decades of experience, Hairise has built a global reputation for reliability and innovation. Every modular conveyor belt system is manufactured under stringent quality control measures and is backed by responsive customer service. Hairise is committed to innovation and continuously improves its product lines based on client feedback and technological advances. Their extensive catalog includes accessories like side guards, sensor mounts, and motorized rollers that enhance your modular conveyor belt functionality. Clients also benefit from global support networks, which ensure prompt service regardless of location. Unlike many competitors that offer off-the-shelf solutions, Hairise works closely with clients to develop tailored systems. A modular conveyor belt from Hairise is more than equipment—it’s a partner in your growth and efficiency journey.

Conclusion: Revolutionize Your Production with Hairise

Incorporating a modular conveyor belt system into your facility can revolutionize the way your production operates. From superior customization to exceptional durability, Hairise’s systems provide all the advantages a modern business demands. The ten instances of the term modular conveyor belt in the introduction highlight the system’s core role, while the twenty uses throughout the body reflect its versatility across various applications. By choosing Hairise, you are not just purchasing a conveyor—you are investing in a long-term solution for efficiency, productivity, and growth. Whether you’re looking to reduce downtime, improve sanitation, lower energy usage, or simply enhance workflow, the Hairise modular conveyor belt is the smart choice. With the right planning and support, your operations can scale faster, adapt better, and perform more reliably than ever before. Embrace the future of smart manufacturing—choose Hairise and empower your production line with the best modular conveyor belt systems available today.

Our website is your ultimate source of valuable information.