In today’s fast-paced electronics industry, finding dependable OEM ODM assembly services is critical to staying competitive and delivering high-quality products to market on time. At Keiteq Direct, we specialize in providing end-to-end OEM ODM assembly services from our state-of-the-art facility in Malaysia, serving clients worldwide with reliability, efficiency, and precision.

Whether you’re a startup bringing a prototype to life or a global brand seeking scalable production, our team at Keiteq Direct is here to support every stage of your electronic manufacturing journey.

What Are OEM and ODM Assembly Services?

Before diving into the capabilities of Keiteq Direct, it’s essential to understand the distinction between OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services:

- OEM Services: The client provides the product design and specifications. The manufacturer (like Keiteq Direct) is responsible for the production, assembly, and quality assurance.

- ODM Services: The manufacturer designs the product based on a concept or basic requirements provided by the client, and handles all aspects of development and manufacturing.

Both services aim to streamline product development, reduce time to market, and maintain strict quality control—all of which are part of the comprehensive solutions offered by Keiteq Direct.

Why Choose Keiteq Direct for OEM ODM Assembly Services?

At Keiteq Direct, we pride ourselves on being more than just a manufacturing partner. We offer a turnkey solution that covers every aspect of OEM ODM assembly services, including:

- Product design and engineering

- PCB fabrication and assembly

- Prototyping and testing

- Component sourcing and procurement

- Quality assurance and compliance

- Final assembly and packaging

- Logistics and delivery

By managing the entire process under one roof, we reduce complexity, lower costs, and ensure better communication throughout the production cycle.

Our Expertise in Electronic Manufacturing Services in Malaysia

Malaysia has become a global hub for electronic manufacturing, offering an ideal mix of cost efficiency, skilled labor, and advanced infrastructure. Keiteq Direct leverages OEM ODM assembly services these advantages to deliver world-class OEM ODM assembly services for clients across various industries:

- Consumer electronics

- Medical devices

- Automotive electronics

- Industrial automation

- IoT and smart devices

- Telecommunication equipment

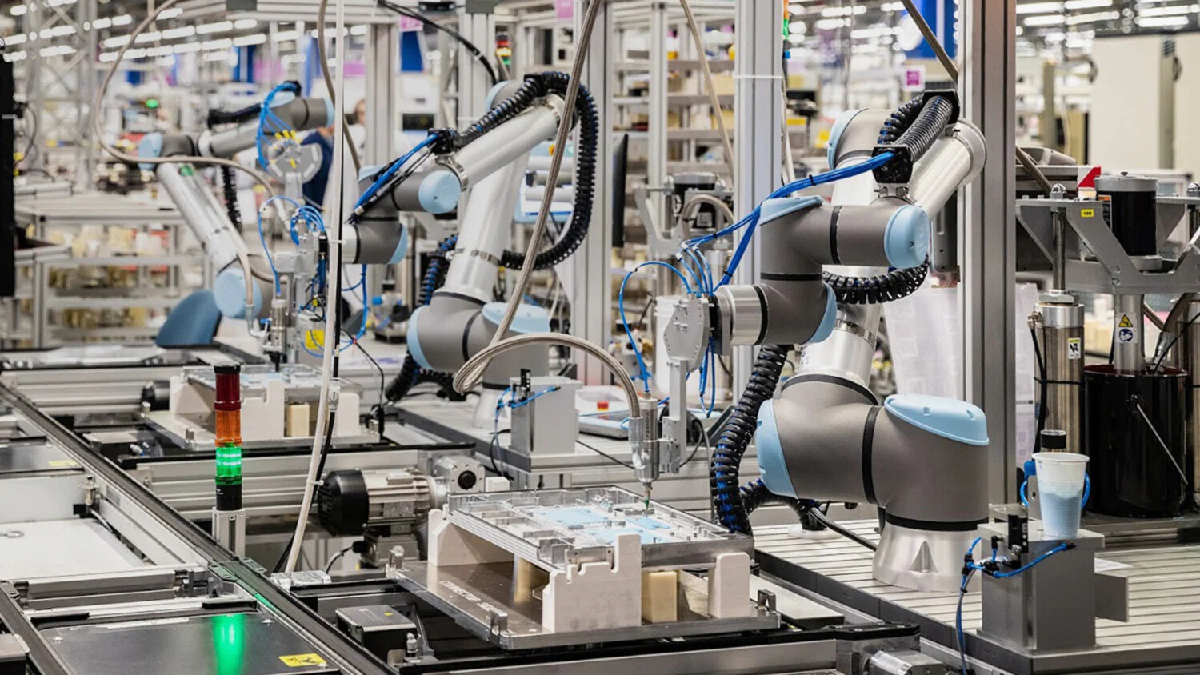

Our Malaysian facility is equipped with modern SMT lines, AOI inspection systems, reflow ovens, and ESD-safe assembly stations to ensure every unit is built to the highest standards

Key Advantages of Partnering with Keiteq Direct

1. Scalable Production Capacity

From small batch prototyping to high-volume production, our OEM ODM assembly services flexible infrastructure accommodates your needs at every stage. We adapt quickly to changes in demand, helping you remain agile in a dynamic marketplace.

2. End-to-End Supply Chain Management

Keiteq Direct handles the entire supply chain—from sourcing components to final product shipment. Our longstanding relationships with global suppliers help us secure high-quality components at competitive prices, minimizing lead times and mitigating risks.

3. Engineering & Design Support

Our in-house engineering team collaborates closely with clients to refine product designs, improve manufacturability, and ensure compliance with regulatory standards OEM ODM assembly services. Whether you require a complete product design or need help optimizing an existing schematic, we’re here to assist.

4. Advanced Quality Control

Quality is at the core of our OEM ODM assembly services. Every product goes through rigorous inspections, including AOI, functional testing, burn-in tests, and more OEM ODM assembly services. We are ISO 9001 certified and adhere to IPC standards to guarantee excellence.

5. Cost Efficiency without Compromise

Manufacturing in Malaysia allows Keiteq Direct to provide competitive pricing without sacrificing quality. You benefit from cost-effective solutions backed by high performance and consistency.

The Keiteq Direct OEM ODM Assembly Process

Here’s a closer look at our streamlined process to bring your electronic product to life:

Step 1: Project Consultation

We begin by understanding your goals, technical requirements, and budget. Whether it’s an OEM specification or an ODM concept, we tailor our service to fit your vision.

Step 2: Design & Engineering

Our team offers DFM (Design for Manufacturability) support, PCB layout, and firmware development, ensuring your product is optimized for efficient production.

Step 3: Prototyping

We produce functional prototypes quickly for evaluation and testing. This helps in identifying issues early and refining the product before mass production.

Step 4: Component Sourcing

Using trusted supplier networks, we source high-quality, RoHS-compliant components, ensuring traceability and cost control.

Step 5: PCB Assembly

We utilize high-speed SMT machines, reflow soldering, and through-hole soldering to assemble your PCBs with precision.

Step 6: Quality Assurance

Our QA team conducts electrical testing, in-circuit tests, visual inspections, and environmental stress testing to ensure fault-free products.

Step 7: Final Assembly & Packaging

Finished PCBs are assembled into enclosures, labeled, packaged, and prepared for delivery according to your specifications.

Step 8: Logistics & Delivery

We offer international shipping options and handle all customs and documentation, ensuring your product reaches its destination securely and on time.

Industries We Serve

Thanks to our wide-ranging capabilities, Keiteq Direct supports customers in diverse markets:

- Medical Electronics: Compliance-focused manufacturing for patient monitoring, diagnostics, and wearable devices.

- Automotive: Durable electronic assemblies for infotainment systems, sensors, and controllers.

- Industrial Control: Reliable PCB assemblies for automation and control systems.

- IoT Devices: Scalable manufacturing for connected home devices, trackers, and smart sensors.

- Consumer Electronics: From wearables to smart gadgets, we deliver stylish, high-performance products.

Sustainability and Compliance

Keiteq Direct is committed to sustainable manufacturing practices. We adhere to RoHS, REACH, and other environmental regulations to minimize our ecological footprint. Our team continuously explores energy-efficient solutions and responsible sourcing policies to ensure ethical production.

Testimonials From Satisfied Clients

“Keiteq Direct helped us scale from prototype to full production seamlessly. Their OEM ODM assembly services exceeded our expectations at every turn.”

— CTO, IoT Startup

“Reliable, precise, and responsive—Keiteq Direct is the kind of partner every hardware brand needs.”

— Head of Procurement, Consumer Electronics Company

Frequently Asked Questions (FAQ)

1. What’s the difference between OEM and ODM services?

OEM services are based on your design specifications, while ODM services include product design and development handled by the manufacturer. Keiteq Direct offers both, depending on your needs.

2. Can you handle low-volume production runs?

Absolutely. We provide flexible batch sizes, including small-volume runs for prototyping or niche products.

3. Do you provide design support for new product development?

Yes. Our engineering team offers complete design assistance, including schematic design, PCB layout, and DFM analysis to ensure optimal manufacturability.

Let’s Build Something Together

At Keiteq Direct, we understand that bringing an electronic product to market involves more than just manufacturing—it’s about trust, innovation, and performance. Our reliable OEM ODM assembly services in Malaysia are designed to provide you with the confidence and capability to compete in today’s tech-driven world. For more knowledge visit our site: sunnymoor