The modern electronics industry runs on precision, innovation, and efficiency — and at the heart of it all lies the printed circuit board assembly (PCBA) process. Every electronic device, from your smartphone to advanced industrial machinery, relies on a carefully assembled PCB to function flawlessly. When you’re searching for printed circuit board assembly suppliers, you’re not just looking for a manufacturer; you’re searching for a partner that can bring your designs to life with exceptional quality, speed, and reliability. That’s where HongRong stands out as a trusted one-stop solution for quality PCBA manufacturing.

The Role of Printed Circuit Board Assembly in Modern Electronics

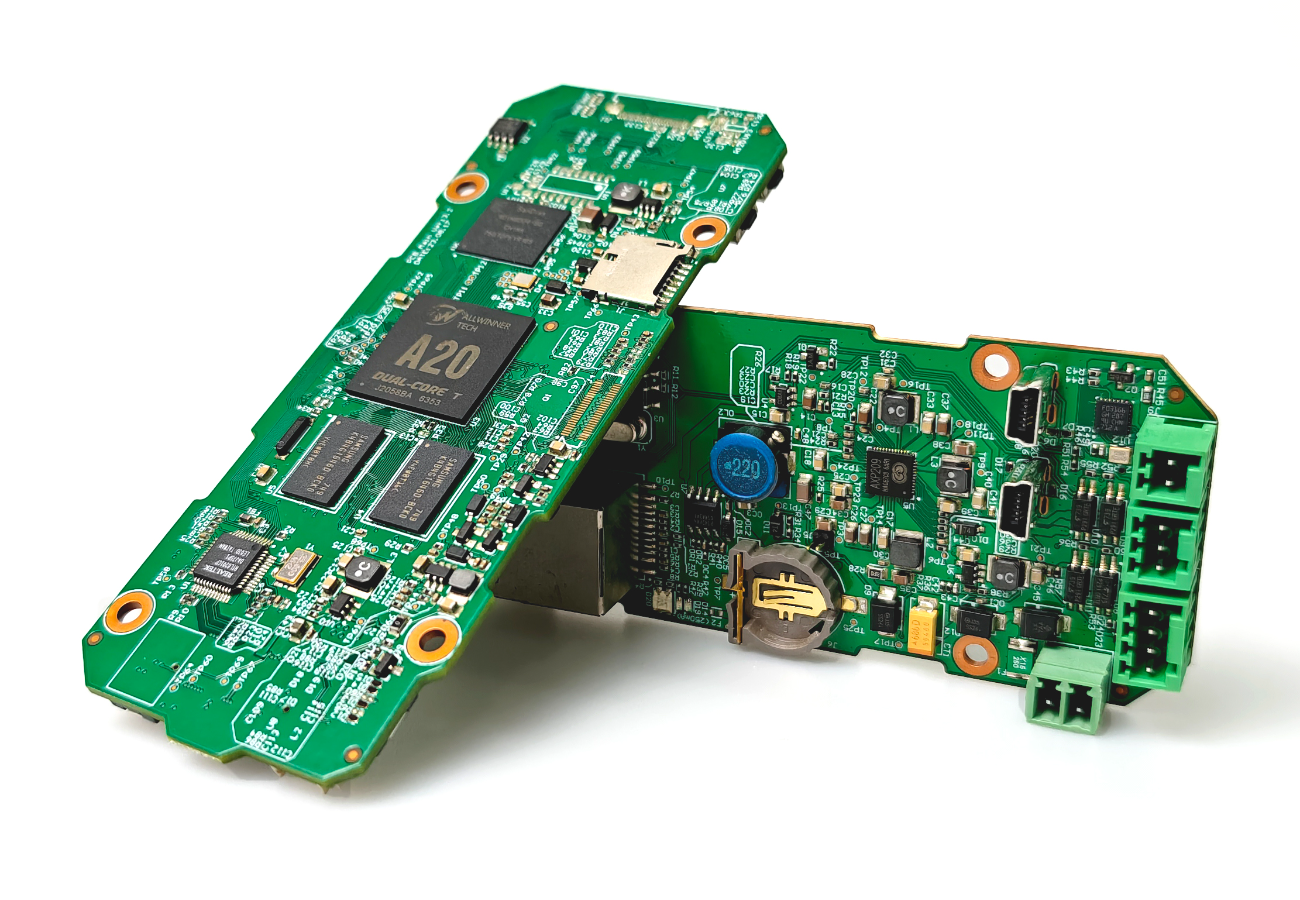

Before diving into why printed circuit board assembly suppliers play such a crucial role, it’s important to understand the process itself. PCBA is the stage where bare printed circuit boards are populated with electronic components. This process transforms a static board into a functional electronic circuit, ready to power everything from consumer electronics to aerospace systems. The assembly process typically involves surface-mount technology (SMT), through-hole technology (THT), or a combination of both. It requires a combination of high-precision machinery, skilled technicians, and rigorous quality control procedures to ensure performance and reliability printed circuit board assembly suppliers.

Why Choosing the Right Printed Circuit Board Assembly Supplier Matters

When selecting from the wide array of printed circuit board assembly suppliers, the difference between a mediocre and an exceptional partner can have a lasting impact on your business. The right supplier ensures:

- Consistent product quality with minimal defects

- On-time delivery to meet your market deadlines

- Compliance with industry standards and certifications

- Scalability to handle both prototypes and high-volume production

- Technical expertise for design optimization and cost efficiency

Choosing poorly, however, can lead to production delays, costly rework, or even product recalls. In the fast-moving electronics industry, these setbacks can significantly damage your brand reputation and profitability.

HongRong – Your Trusted Partner Among Printed Circuit Board Assembly Suppliers

At HongRong, we pride ourselves on being more than just a PCBA manufacturer. We act as a true extension of your engineering and production team, offering tailored solutions that ensure your electronic products exceed expectations. As one of the most reliable printed circuit board assembly suppliers, we deliver exceptional value through:

- Full-Process Manufacturing: From PCB fabrication to component sourcing, assembly, testing, and final inspection, we manage the entire process under one roof.

- Advanced Technology: Our state-of-the-art SMT and THT lines are equipped to handle high-density, multi-layer boards with extreme precision.

- Strict Quality Control: Every board undergoes rigorous inspection using AOI (Automated Optical Inspection), X-ray, and functional testing to ensure zero defects.

- Flexible Order Quantities: Whether you need a few prototypes or large-scale production runs, we scale our services to meet your needs.

- Global Standards Compliance: We meet or exceed IPC, RoHS, and ISO certifications to guarantee industry-compliant products.

The Complete PCBA Manufacturing Process at HongRong

As one of the leading printed circuit board assembly suppliers, HongRong follows a streamlined process designed for efficiency and precision:

1. PCB Fabrication

The journey begins with manufacturing the bare PCB. Using high-quality laminates, precision etching, and advanced layering techniques, we ensure that every board meets tight tolerances and design requirements.

2. Component Procurement

HongRong works with a network of trusted component distributors, ensuring genuine parts at competitive prices. Our procurement team verifies each component’s authenticity and performance to prevent counterfeit issues.

3. Surface Mount Technology (SMT) Assembly

We use high-speed pick-and-place machines to mount SMD components with pinpoint accuracy. Our reflow soldering process ensures consistent solder joints for long-term reliability.

4. Through-Hole Assembly (THT)

For components that require mechanical strength or cannot be surface-mounted, our skilled team handles THT soldering, either manually or via wave soldering.

5. Testing and Inspection

HongRong uses a multi-step inspection process — including AOI, X-ray, and functional testing — to guarantee that each board performs exactly as intended before it leaves our facility.

6. Packaging and Delivery

Finished boards are carefully packaged to protect them from static, moisture, and damage during transit, ensuring they reach you in perfect condition.

What Sets HongRong Apart from Other Printed Circuit Board Assembly Suppliers

Many suppliers can offer basic assembly services, but HongRong distinguishes itself through:

- Engineering Support: Our engineers work closely with your design team to identify cost-saving opportunities, improve manufacturability, and enhance performance.

- Rapid Turnaround: Time is critical in electronics, and we specialize in delivering prototypes in as little as 24–48 hours and production orders with minimal lead times.

- Competitive Pricing Without Compromising Quality: Our efficient processes and supplier relationships allow us to offer affordable pricing while maintaining high standards.

- Custom Solutions: We adapt our processes to meet unique product requirements, from medical devices to automotive electronics.

Industries We Serve

As a versatile name among printed circuit board assembly suppliers, HongRong supports clients across multiple industries, including:

- Consumer Electronics – Smartphones, tablets, wearables

- Industrial Equipment – Automation systems, control boards

- Medical Devices – Patient monitoring, diagnostic equipment

- Automotive Electronics – Engine control units, infotainment systems

- Telecommunications – Networking devices, fiber optic systems

- Aerospace and Defense – Navigation, communication, and safety systems

Each sector demands different standards and performance metrics, and HongRong is equipped to meet them all.

Key Benefits of Partnering with HongRong

When you choose HongRong over other printed circuit board assembly suppliers, you gain:

- A single point of contact for all your PCB needs

- Reduced risk of errors due to end-to-end process control

- Faster time-to-market for your products

- Access to experienced engineers for troubleshooting and optimization

- Assurance of compliance with the latest industry standards

Future Trends in Printed Circuit Board Assembly

The electronics industry is evolving rapidly, and printed circuit board assembly suppliers must stay ahead of the curve. HongRong invests in emerging technologies to ensure our clients remain competitive. Key trends include:

- Miniaturization: Smaller, more compact boards to fit modern device designs

- High-Density Interconnect (HDI): Advanced layering techniques for complex circuits

- Flexible PCBs: Boards that can bend or fold for innovative applications

- IoT Integration: Assembly processes optimized for smart devices and sensors

- Sustainable Manufacturing: Eco-friendly materials and waste reduction strategies

Why HongRong is the Smart Choice for Your PCBA Needs

With decades of combined experience, advanced manufacturing capabilities, and a commitment to excellence, HongRong stands as a benchmark for quality and reliability in the PCBA industry. Whether you’re developing a groundbreaking new product or scaling up production for an established one, we provide the expertise, infrastructure, and dedication you need to succeed.

Frequently Asked Questions (FAQ)

Q1: What makes HongRong different from other printed circuit board assembly suppliers?

A1: HongRong offers end-to-end PCBA services, from fabrication to testing, with advanced technology, strict quality control, and engineering support tailored to your project.

Q2: Can HongRong handle both prototype and mass production orders?

A2: Yes, we offer flexible services that cater to both small prototype runs and high-volume production with equally high quality standards.

Q3: How does HongRong ensure the quality of its PCBA products?

A3: We implement multi-stage inspections, including AOI, X-ray, and functional testing, along with sourcing only genuine components from trusted distributors.

Conclusion – Partner with HongRong for Superior PCBA Manufacturing

In the competitive world of electronics, partnering with the right printed circuit board assembly suppliers can be the difference between product success and failure. HongRong offers the perfect blend of technology, expertise, and reliability to bring your designs to life with unmatched quality. With our comprehensive services, competitive pricing, and commitment to excellence, we are your one-stop solution for all PCBA manufacturing needs. Contact us today and take the first step toward building products that outperform expectations.

Visit our website for more information.