In today’s competitive manufacturing landscape, maintaining impeccable product quality is not just desirable—it’s essential. Companies are increasingly turning to advanced technologies to enhance quality control processes, and machine vision has emerged as a game-changer. By automating inspection and defect detection, machine vision systems bring unprecedented accuracy and speed to quality control, helping manufacturers reduce waste, improve consistency, and boost customer satisfaction.

At Sciotexe, we delve into how machine vision technology can unlock superior quality control and transform your production line.

What is Machine Vision?

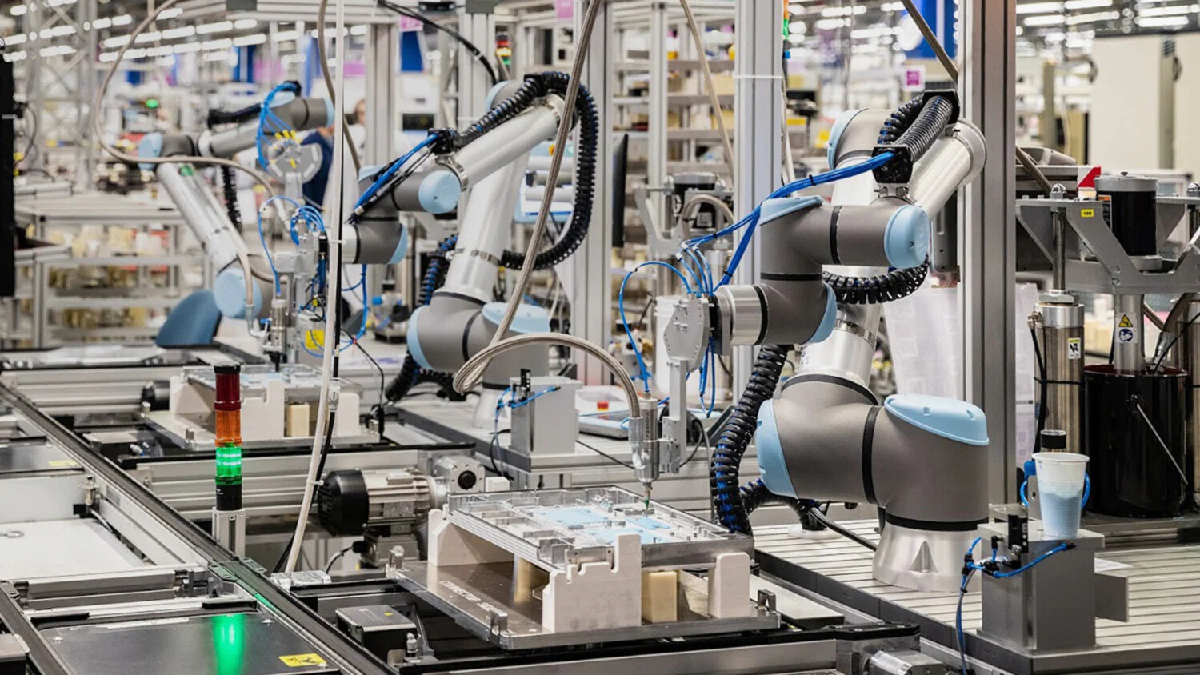

Machine vision refers to the technology and methods used to provide imaging-based automatic inspection and analysis for applications such as automatic inspection, process control, and robot guidance. Essentially, it allows machines to “see” and interpret visual information in real time, much like human vision but with greater precision and repeatability.

Unlike human inspectors, machine vision systems use cameras, lighting, and sophisticated algorithms to analyze products at high speeds. This makes it ideal for industries where precision and consistency are paramount.

Why Machine Vision is Vital for Quality Control

Quality control is a cornerstone of any manufacturing process. Traditional manual inspections, while valuable, are often slow, inconsistent, and prone to human error. Here’s why machine vision stands out:

1. Enhanced Accuracy and Consistency

Machine vision systems can detect defects or anomalies at micron-level precision, far beyond human capability. This ensures that every product meets strict quality standards without fail.

2. Increased Inspection Speed

Machine vision performs inspections rapidly, significantly faster than manual processes. This increased throughput reduces bottlenecks on the production line and boosts overall productivity.

3. Objective and Repeatable Results

Unlike human inspectors who may have subjective biases or fatigue, machine vision provides uniform and repeatable inspections, ensuring quality remains consistent across batches.

4. Cost Efficiency Over Time

Although initial investment in machine vision technology may be high, the long-term benefits such as reduced scrap rates, fewer recalls, and less labor cost lead to substantial savings.

Key Applications of Machine Vision in Quality Control

Machine vision is versatile and can be integrated into many stages of manufacturing. Some common applications include:

Visual Inspection and Defect Detection

Automatically identifying scratches, dents, discoloration, or misalignments in products.

Measurement and Dimension Verification

Checking dimensions and tolerances to ensure parts fit perfectly and operate as intended.

Assembly Verification

Confirming that components are correctly assembled, preventing costly downstream failures.

Surface and Texture Analysis

Detecting surface defects like cracks or inconsistencies in materials such as metals, plastics, or fabrics.

Barcode and Label Verification

Ensuring labels are present, readable, and correctly applied to products or packaging.

How Machine Vision Works in Quality Control

A typical machine vision system consists of:

- Cameras and Optics: Capture high-resolution images of the product.

- Lighting: Proper illumination is critical to highlight defects and features.

- Image Processing Software: Analyzes images using algorithms to detect defects or deviations.

- Communication Interface: Integrates with manufacturing equipment to trigger actions like rejection or sorting.

This integration allows real-time quality control that can adapt to various production scenarios, ensuring a smooth and reliable workflow.

Benefits of Implementing Machine Vision at Sciotexe

At Sciotexe, we understand the importance of flawless quality control in boosting brand reputation and reducing operational risks. Our expertise in machine vision systems offers several key benefits:

- Customized Solutions: Tailored machine vision setups designed specifically for your product type and inspection requirements.

- Seamless Integration: Compatibility with existing manufacturing lines to minimize downtime during installation.

- Scalable Technology: Easily adjustable for different product sizes or increased production volumes.

- Ongoing Support: Continuous system monitoring and updates to keep your quality control cutting-edge.

Challenges and How to Overcome Them

While machine vision is powerful, it’s not without challenges:

- Initial Cost and Setup Complexity: Investing in the right equipment and software can be expensive.

- Lighting and Environmental Sensitivity: Machine vision performance heavily depends on consistent lighting and environmental control.

- Complex Defect Types: Some defects require sophisticated algorithms and AI for reliable detection.

At Sciotexe, our experienced engineers guide clients through these challenges, offering expert consultation and support to maximize machine vision effectiveness.

Future Trends in Machine Vision for Quality Control

The future of machine vision looks promising with advancements in:

- Artificial Intelligence (AI) and Deep Learning: Enabling smarter defect detection by learning from data and improving over time.

- 3D Machine Vision: Providing detailed surface mapping for even more precise inspection.

- Edge Computing: Allowing faster, real-time processing directly on the factory floor.

- Integration with IoT: Connecting machine vision systems to broader smart factory networks for comprehensive process monitoring.

Conclusion: Unlock Superior Quality Control with Machine Vision

Incorporating machine vision technology into your quality control process is no longer a luxury—it’s a necessity for manufacturers aiming to stay ahead. The ability to inspect with greater speed, accuracy, and reliability helps reduce costs, improve product quality, and elevate customer trust.

At Sciotexe, we are committed to helping businesses harness the full potential of machine vision. Whether you’re upgrading your existing system or starting fresh, our expertise ensures you unlock superior quality control that drives success. Our website is your ultimate source of valuable information.

FAQ Section

Q1: What industries benefit most from machine vision in quality control?

Machine vision is widely used in automotive, electronics, food and beverage, pharmaceuticals, packaging, and manufacturing industries—any sector requiring precise inspection and defect detection.

Q2: How does machine vision compare to human inspection?

Machine vision provides faster, more consistent, and more accurate inspections without fatigue or subjectivity, making it superior for high-volume and high-precision environments.

Q3: Is machine vision difficult to implement in existing production lines?

With expert guidance from companies like Sciotexe, machine vision systems can be seamlessly integrated with minimal disruption, tailored to your specific production needs.